- Home

- Company

- MACHINE CATEGORY

- APPLICATION CATEGORY

- Resource

- Blog

- Contact us

- Home

- Company

- MACHINE CATEGORY

- APPLICATION CATEGORY

- Resource

- Blog

- Contact us

Linyco is our sub-brand

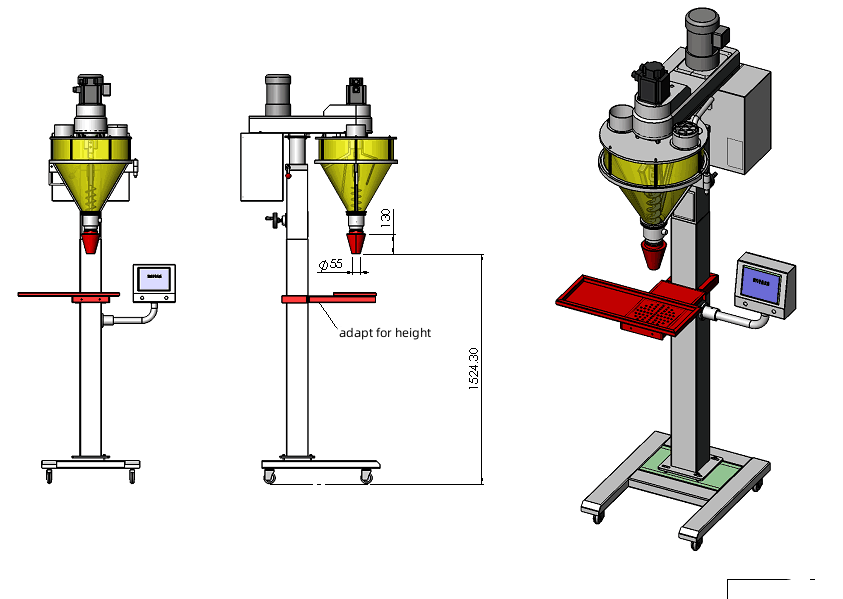

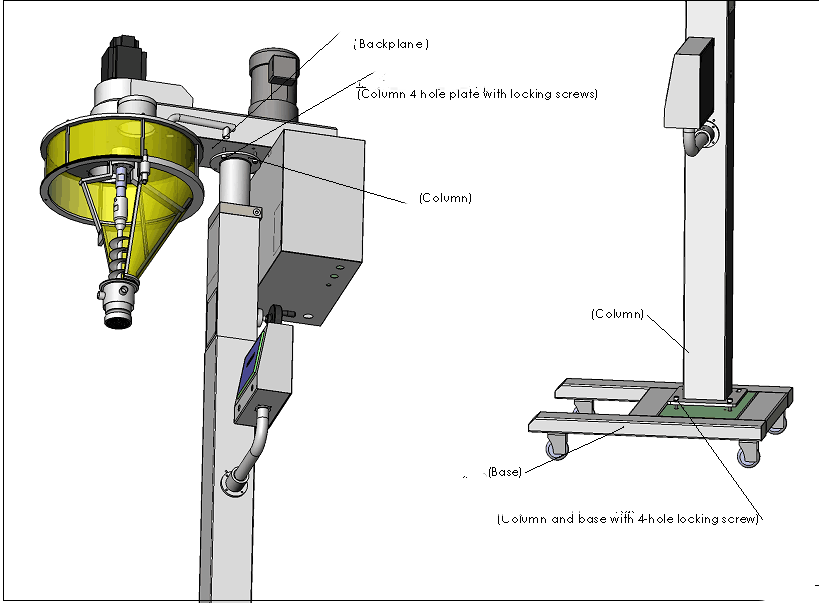

A powder auger filler is a machine used to accurately fill powders and other dry products into bags, containers, or other packaging. The machine is designed with an auger, which is a rotating screw that works to draw the powder into the filler, measure it, and dispense it into the packaging. The auger can be designed in various sizes and shapes to accommodate different types of powders and densities.

The filling process for the powder auger filler involves the powder being fed into the hopper, where it is then drawn down into the screw conveyor. The amount of powder dispensed is determined by the speed and rotation of the auger, as well as the size and pitch of the screw. The auger then dispenses the powder into the packaging, which can be a bag, bottle, or container.

Powder auger fillers are commonly used in the packaging of products such as flour, spices, powdered drink mixes, pharmaceuticals, and other dry goods, where the accurate and precise filling is required.

Accurate filling: Powder auger filler provides highly accurate filling of the products. It uses a rotating auger to measure and dispense each product.

Versatility: The machine can be used to fill a wide variety of products, including free-flowing and non-free-flowing products.

Efficiency: The machine offers high efficiency in terms of production rates and filling accuracy.

Easy to operate: Powder auger filler is easy to operate, and it can be integrated with other machines to form a complete production line.

Customizable: The machine can be customized to meet specific production requirements, such as the size of the product, container, and the desired level of automation.

| Auger Filler | |

|---|---|

| Package Weight | 10 – 1000g |

| Packing Accuracy | ≤ ±1%(≤ 100g) ≤ ±0.5%(100 – 1000g) |

| Filling Speed | 40 – 120bags/min |

| Power | 3p 380v 50hz |

| Total Power | 1.0 / 1.5kw |

| Weight | 140kg |

| Volume | 1300 × 850 × 1850mm |