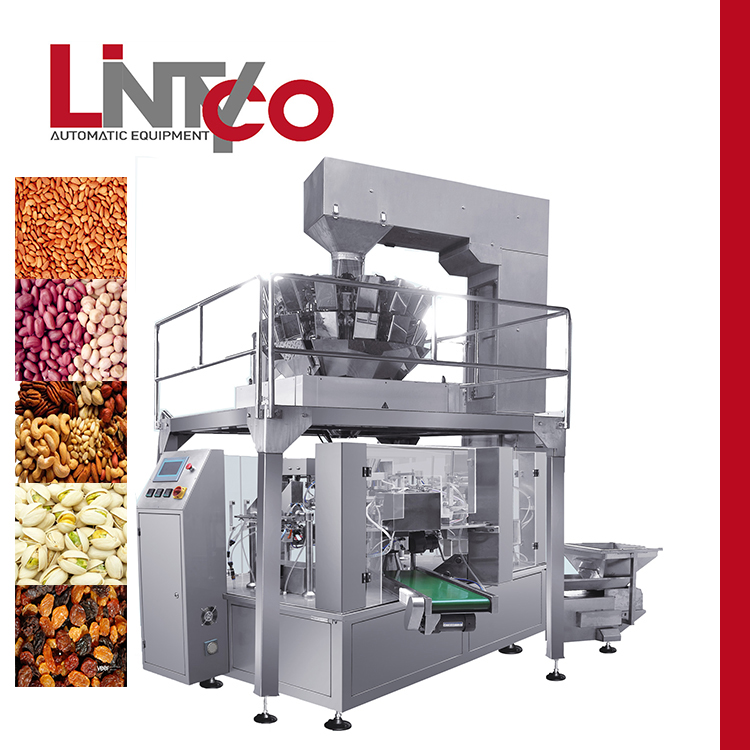

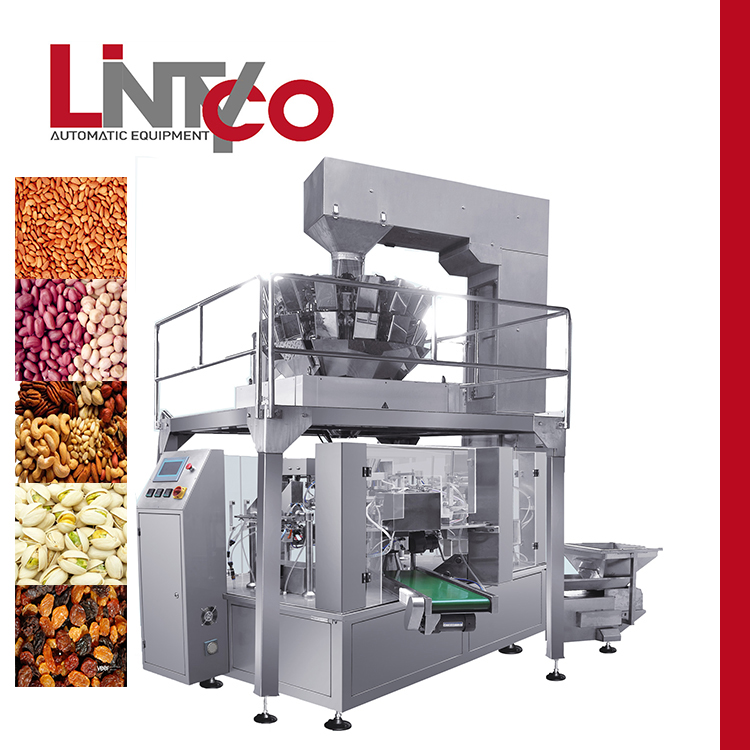

Automatic Rotary Premade Doypack Pouch Granule Nuts Packing Machine Manufacture

Summery |

1. Easy to change bag size and bag type.

2. Easy to adjust the Printer range.

3. Machine optoelectronic system can check bag, material filling, and sealing situation to avoid failure.

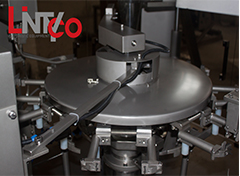

4. Stable worktable with low noise and long life as the bottom drive system.

5. High bag opening effective and low machine failure rate.

6. Sample wiring arrangement with high-quality electronic components |

Parameters |

| LTC8-200 | LTC8-260 | LTC8-300 |

Bags size | W:80~210mm L:100~300mm | W:120~250mm L:100~400mm | W:200~300mm L:100~400mm |

Bag type | Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag | Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag | Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag |

Filling Volume | 30 – 1900g depending on type of products | 30-2000g depending on type of products | 100-2500g depending on type of products |

Capacity | 25-60 bags/min for different material and different bag | 25-60 bags/min for different material and different bag | 25-60 bags/min for different material and different bag |

Dimension | 1.140*1.500*1.560m | 2.46*1.83*1.46m |

|

Weight & power supply | 1400kgs/1500kgs/1600kgs-1800kgs 380v 50HZ 3P 2.5kw-5kw |

Compress air requirement | 0.6-1m³/min supply by user |

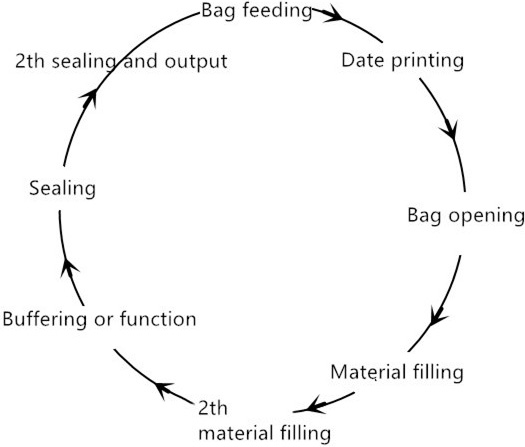

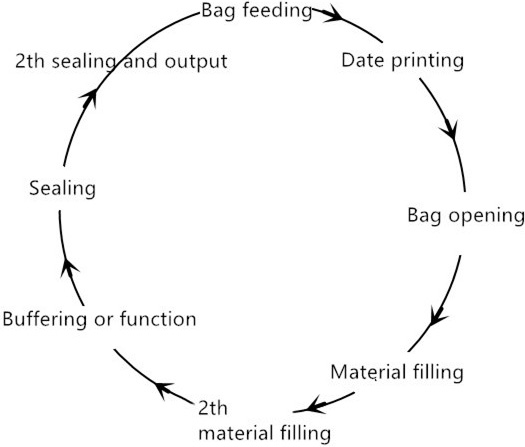

Working flow | 1. Bag feeding

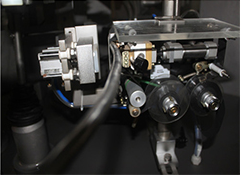

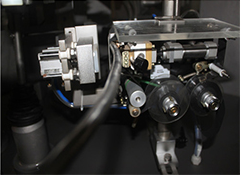

2. Date printing

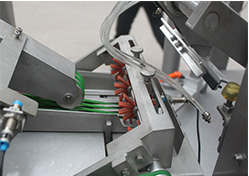

3. Zipper opening

4. Bag opening

5. Material filling

6. 2th material filling

7. Buffering or function

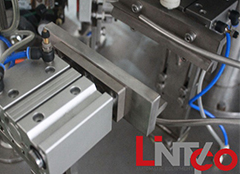

8. 2nd sealing and output |

------------------------------------------------------------------------------------------------------------------------------------------

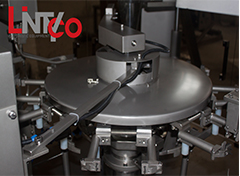

Working Process

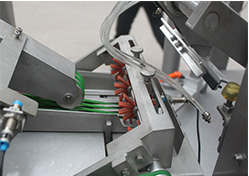

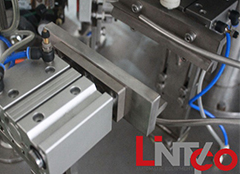

Working Table Printer Vertical Bag Feeder

Liquid filler Sealing Bar Horizontal Bag Feeder

Popcorn Bag Device Bag Zipper Device OperativeSurface

Wenzhou BenGang Machinery Co., Ltd is a professional packing solution company that specializes

in food assembly line and packing machine lines. We have our own R&D, machine making, marketing

, and after-sales department to service clients all over the world with experience for years..

BenGang provides machine testing and factory payout drawing before order, machine-making process report

during the order, machine OEM,24h online or field aftersales service