- Home

- Company

- MACHINE CATEGORY

- APPLICATION CATEGORY

- Resource

- Blog

- Contact us

- Home

- Company

- MACHINE CATEGORY

- APPLICATION CATEGORY

- Resource

- Blog

- Contact us

It's often said that technology is the primary productivity force. When it comes to China, the country has made remarkable technological advancements over the years, particularly in the field of machinery which formerly relied heavily on imported foreign products, but has now shown an ability for independent production. Take packaging machinery as an example - there are now many domestic production companies that specialize in this field, producing advanced technology.

With that said, for factories or companies that require automatic packaging machines, how can they select the appropriate packaging machinery that suits their needs? Today's article will address some considerations when selecting an automatic packaging machine, beginning with the measuring method.

Currently, automatic packaging machines come with several measuring methods, such as counting method, microcomputer combination method, screw measuring method, volumetric measuring method, and injection pump measuring method. Each measuring method applies to different materials, with varying levels of accuracy.

1、Syringe pump dosing method

This measuring method is suitable for liquid materials such as tomato sauce, edible oil, honey, laundry detergent, chili sauce, shampoo, instant noodle seasoning, and other liquids. It uses a cylinder stroke measuring principle that can adjust the packaging capacity freely and has a measurement accuracy of <0.3%. If you need to package liquid materials, this measuring method is the most popular option available.

2、Measuring cups measuring method

This measuring method is suitable for industries with small particles and regular shapes, such as rice, soybeans, refined sugar, corn kernels, sea salt, table salt, and plastic particles. Among many measuring methods, it is currently one of the more cost-effective and has high measuring accuracy. If you need to package regularly shaped small particle materials and also want to save on costs, then a measuring cup automatic packaging machine is the most suitable solution for you.

3. Screw metering method

This measuring method is commonly used for powdered materials, such as flour, rice noodle rolls, coffee powder, milk powder, milk tea powder, seasoning, chemical powder, etc., and can also be used for small particle materials. It is also a widely used measuring method, but if you do not have such high requirements for packaging speed and accuracy, you can consider using an automatic packaging machine with a measuring cup.

4、Microcomputer combination measurement method

The microcomputer combination weighing method is suitable for irregular block-like and granular materials, such as candy, puffed food, small biscuits, roasted nuts and dried fruits, sugar, frozen food, hardware and plastic products, etc.

(1) Single scale. Using a single scale to weigh has a low production efficiency, and the accuracy will decrease when the weighing speed is increased.

(2) Multiple scales. Using multiple scales for weighing can greatly improve production efficiency, especially for high-precision measurement of coarse grains and block-like materials. Its error will not exceed ±1%, and it can weigh 60-120 times per minute.

The microcomputer combination weighing method is developed to solve problems in traditional weighing methods. Therefore, if you have high requirements for packaging accuracy and speed, you can choose an automatic packaging machine with this weighing method.

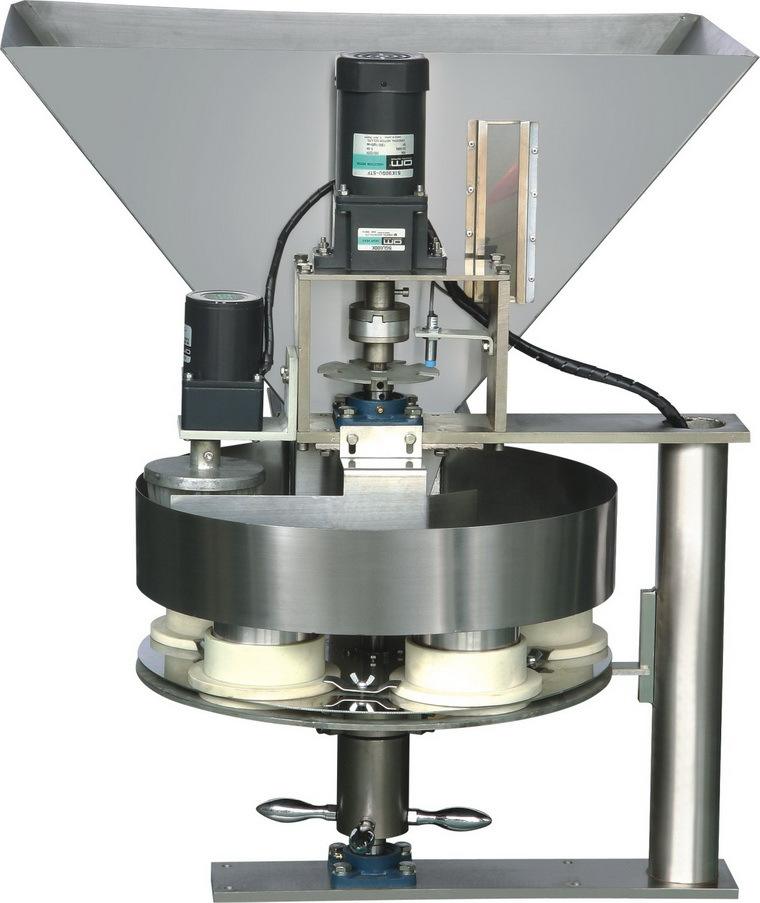

5、Counting and measuring method

The counting weighing method is used to determine the number of products in each specified batch. It is widely used in the packaging of bar, block, sheet, and granular products. It is divided into single-piece counting, multi-piece counting, and turntable counting methods. Therefore, if you need a certain quantity of packaged materials, you can use a counting automatic packaging machine.