- Home

- Company

- MACHINE CATEGORY

- APPLICATION CATEGORY

- Resource

- Blog

- Contact us

- Home

- Company

- MACHINE CATEGORY

- APPLICATION CATEGORY

- Resource

- Blog

- Contact us

1. For any powder production such as coffee powder, coconut powder, chili powder, spicy powder, milk powder...

2. For premade pouch such as doypack pouch, zipper pouch, quad seal zipper powder, gusset pouch...

3. 3 models for 3 different bag size range.

4. More talk add whatsapp 008613868827095

Summery | |||

1.Easy to change bag size and bag type. 2.Easy to adjust Printer range. 3.Machine optoelectronic system can check bag,material filling and sealing situation to avoid failure. 4.Stable worktable with low noise and long life as the bottom drive system. 5.High bag opening effective and low machine failure rate. 6.Sample wiring arrangement with high quality electronic components | |||

Parameters | |||

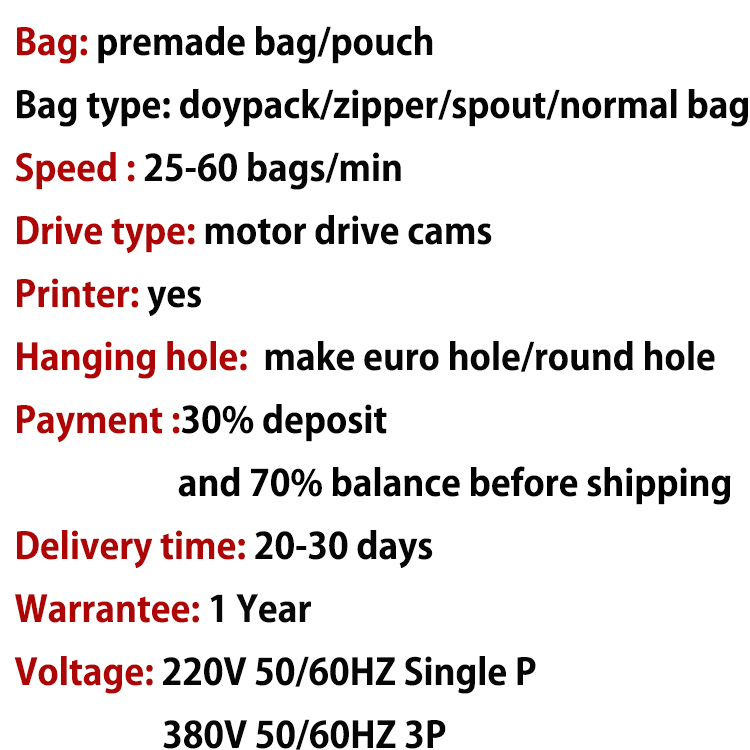

LTC8-200 | LTC8-260 | LTC8-300 | |

Bags size | W:80~210mm L:100~300mm | W:120~250mm L:100~400mm | W:200~300mm L:100~400mm |

Bag type | Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag | Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag | Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag |

Filling Volume | 30 – 1900g depending on type of products | 30-2000g depending on type of products | 100-2500g depending on type of products |

Capacity | 25-60 bags/min for different material and different bag | 25-60 bags/min for different material and different bag | 25-60 bags/min for different material and different bag |

Dimension | 1.140*1.500*1.560m | 2.46*1.83*1.46m | |

Weight & power supply | 1400kgs/1500kgs/1600kgs-1800kgs 380v 50HZ 3P 2.5kw-5kw | ||

Compress air requirement | 0.6-1m³/min supply by user | ||

Working flow | 1. Bag feeding 2. Date printing 3. Zipper opening 4. Bag opening 5. Material filling 6. 2th material filling 7. Buffering or function 8. 2th sealing and output | ||